The Norwegian startup BioSort develops sensor-based solutions for optimizing fish resources. The goal is to replace manual inspection and random sampling by automated processes and monitoring derived from modern production processes. By handling fish at the individual level, you get both increased fish welfare and higher production yields - good for both the environment and the bottom line.

BioSort's product, iFarm, monitors the health, lice and growth of each fish in a cage. Individual fish can be removed, such as carriers and lice collectors. Today, all fish are treated for salmon lice, for example, when only a small proportion of fish need treatment. With the iFarm system, each fish receives a unique health record that is updated weekly. The goal is to at least halve the mortality rate by taking out sick fish and treating only those who need it.

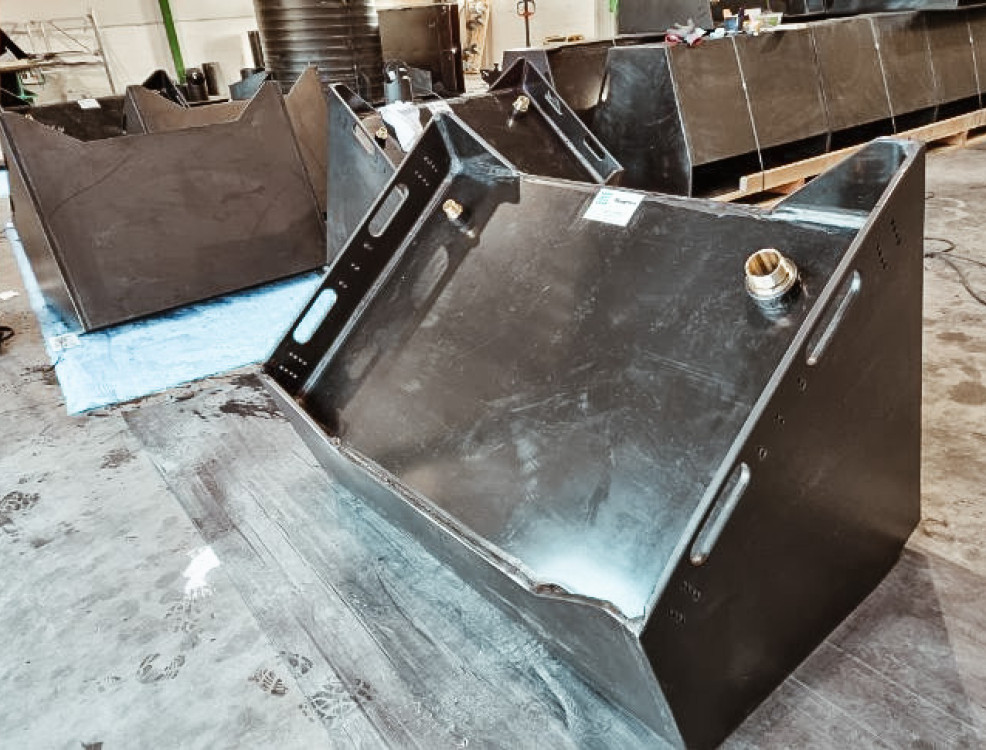

The system itself consists of a net roof and an upper swimming volume with access to the surface, and is mounted in standard open cages in the sea. In order to achieve a smooth process during de-lice, BioSort identified the need for buoyancy elements to raise and lower the structure. Bernt Saugen, CTO of BioSort, came to Bluegreen for assistance.

– It was a challenge that emerged. Bluegreen helped us with drawing, engineering and production of the buoyancy elements, all finished in just a couple of weeks, says Saugen. – We greatly appreciate having skilled suppliers who can deliver in a short time.

Now there are nine sets of elements on the way up to Vesterålen, where they will be retrofitted on Cermaq's cages in beautiful surroundings in Langøyhovden.