We are Norway's leading experts in thermoplastic fusion and EPCI solutions. We have experience from the world's largest structures in PE (polyethylene) and deliver complex infrastructure projects and prefabricated products.

Be om tilbud

We perform butt fusion, extrusion welding, membrane fusion and electro-socket fusion of thermoplastics. Our equipment is modern and efficient, with data logging / documentation and a high degree of automation. We own equipment up to Ø1200 mm and have personnel who are certified up to Ø2000 mm.

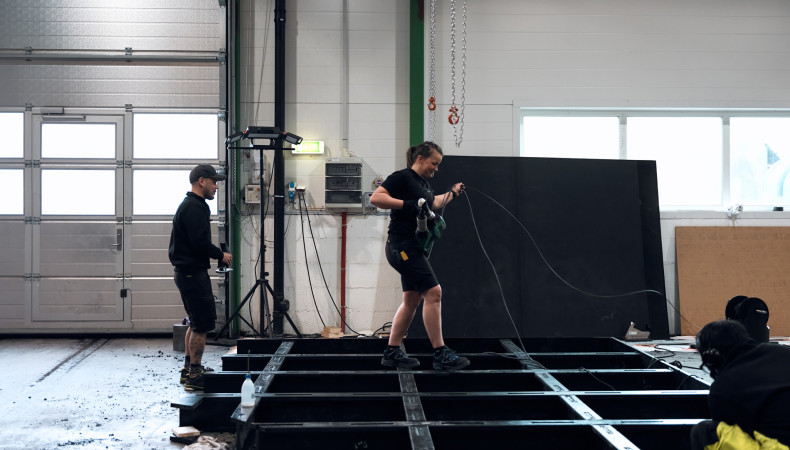

We build parts, fittings and structures in our prefab workshop for easy installation on site. We have a separate production area by the sea for shipping by boat or barge, when this cannot be done on the road.We also have a 900 m2 permanent prefabrication facility with state-of-the-art equipment, including a three-axled milling machine.

We analyze, develop and design structures and infrastructure in thermoplastics with a focus on sustainable solutions. All work is thoroughly documented according to relevant standards and customer requirements. We have special expertise in development and documentation of fusion/welding procedures.

We have fusion machines and special equipment for efficient and high quality installation on site. We also do fusion projects for other contractors. Some of our equipment is particularly suitable for pipes and plate constructions.

Bluegreen is a distribution partner of McElroy for the Scandinavian market. McElroy supplies the most robust equipment for plastic fusion, and is a world leader in efficiency and documentation. Our McElroy fusion machines have additional equipment such as polyhorse for gentle and efficient installation of pipes in the field. These also have data documentation of the welds and are operated by a minimum of personnel due to the high degree of automation. The McElroy machines have no problems in meeting the requirements of maximum heating plate removal time, where several other equipment is struggling due to manual operations under time pressure, especially for larger dimensions. This is crucial for a good joint and meeting the codes.