Plastic welding often involves heavy manual work. To save arms and shoulders, as well as ensure good documentation of welding quality, we are developing a self-propelled fusion machine.

Many fusion jobs require the use of handheld welding machines. Although we use extrusion welders from Leister, which has a strong focus on ergonomics and HSE, we cannot escape the fact that it is heavy manual labor. With a weight of around 12 kg, even the most well-trained welder gets tired arms and shoulders after a long day.

“We were thinking: there must be a smarter way to do this”, says Rune Dorholt, project manager at Bluegreen. “When lining fishing vessels with straight welds up to 6 meters high, for instance, an automatic solution would save both time and shoulders.”

Thomas Sudbø Meinstad, Team Manager Plastic Mechanic at Bluegreen, set about developing and testing an automatic solution.

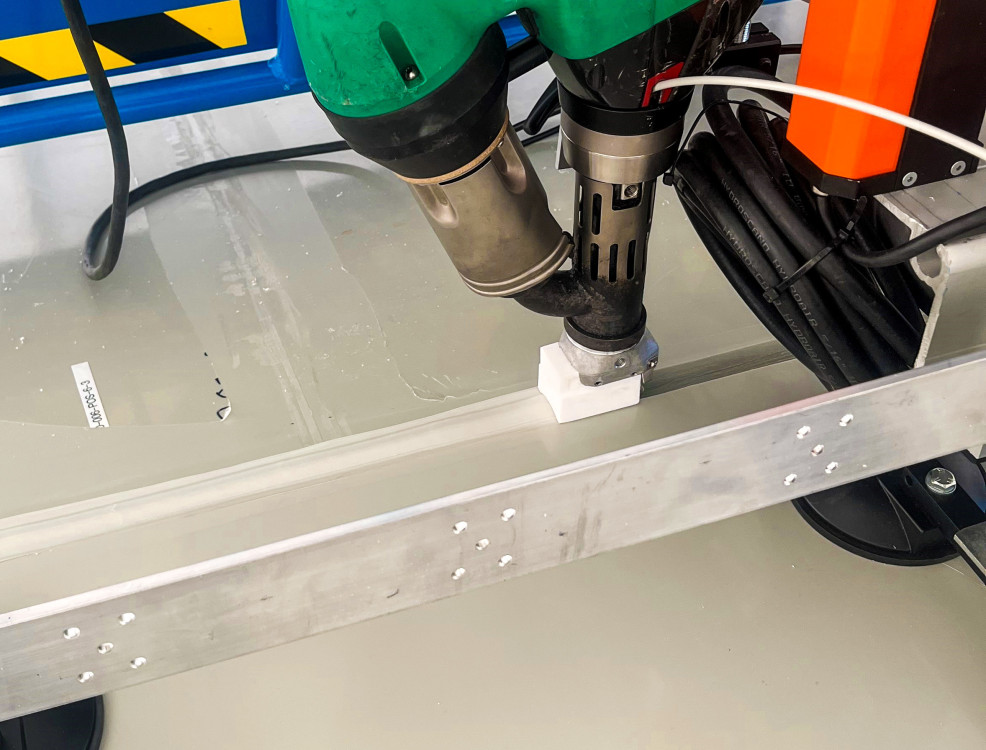

“We mounted a hand-held welding machine on top of a wheeled motor, and a rail along which the welding machine could crawl. We control the machine with a remote control and make sure that it pushes the right torque into the weld at all times”, Thomas explains. “We have also developed a solution for automatic logging and documentation.”

Reto Britschigi, product manager at Leister, is impressed by the innovation:

“Bluegreen makes some of the world's largest PE constructions. They demand a lot from the machines they use and thus push development further. For Leister, as a tool supplier, it is inspiring and important to be close to our customers and get a deep understanding of their needs. This way, our engineers can create ever better products.”

Rune Dorholt is very satisfied with the self-propelling fusion machine:

“We are actually already using the fusion machine when lining fish tanks and building large closed fish farm structures. Not only is it good for HSE, but the welds also maintain a really high quality. We avoid the post-work of grinding the joints that occurs when the plastic welder has to start and stop to change positions. The machine welds with uniform pressure meter after metre, And we can log and document the welding quality in a way that has not previously been possible.”

The fusion machine is well suited to all kinds of large thermoplastic constructions. The next step is to develop a solution for "cruise control".