We didn't have to go far to find the expertise we needed to get the groundbreaking "Marine Donut" certified. Ranold, located just across the fjord in Herøya Industrial Park, is among Norway's leading environments in flow expertise.

Nice view from the deck of the Marine Donut. Morten Hansen Jondahl (Ranold), Geir Andresen (Bluegreen), Mikkel Bakli (Ranold).

"For Bluegreen, it has been crucial to be 100% sure that the fish that will live and grow in the facility will thrive. This ensures both good fish welfare and a high-quality end product for the consumer," explains Geir Andresen, partner in Bluegreen and project manager for the construction of Marine Donut.

Marit Kleven, specialist/PhD, has led the deliveries from Ranold's side. The work on the "donut" has mostly consisted of detailed CFD calculations (Computational Fluid Dynamics – numerical fluid dynamics) to verify and optimize the internal flow for increased fish welfare.

"Ranold has conducted detailed analyses of the velocity conditions inside the fish volume to ensure that the large thrusters provide enough water thrust for the fish to have good trim. The analyses also show that there are no stagnant zones anywhere in the water volume. Such zones can be catastrophic for the fish in the facility," says Kleven.

In 2016 and 2022, Ranold conducted CFD analyses on the Marine Donut concept, evaluating both external forces on the floating structure and internal flow.

"We have also performed stability assessments to document buoyancy and stability according to NS9415:2021. We have looked at stability in normal situations as well as in an accident scenario based on a worst-case scenario," says Kleven.

The Aquaculture Act, aimed at promoting the profitability and competitiveness of the aquaculture industry within the framework of sustainable development and value creation along the coast, stipulates that all floating aquaculture facilities must have a facility certificate before they can be put into use. The new technical regulation for aquaculture facilities at sea (NYTEK) became effective from January 1, 2023.

"Our calculations have assessed the environmental loads applied to Marine Donut from waves, ocean currents, and wind," says Kleven. "The software we have used is developed for traditional ship design, so it has posed challenges to calculate on an unconventional design in plastic."

To verify the modeling work, physical incline tests were conducted on Marine Donut, located off Molde.

"A incline test was performed on Marine Donut at Sekken in November," says Andresen. "The measurements from the physical test were compared with the calculation results performed by Ranold and show a good correlation between calculation and physical measurement."

There was great joy when Aquastructures awarded Marine Donut the "Approved" stamp at the end of November. The facility is now handed over to SalMar, one of the world's largest aquaculture companies. The first fish stocking is expected in this winter.

Read more: Approved Product Certificate. Next step: Enter Fish.

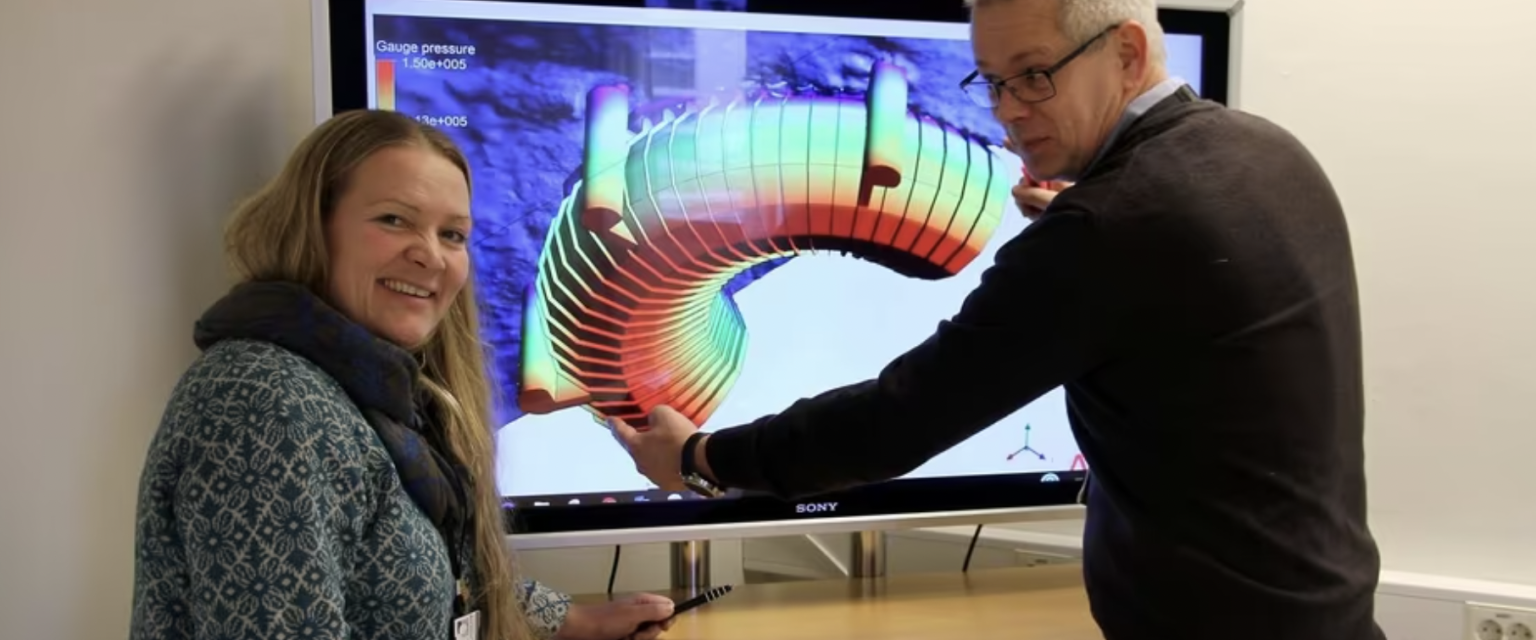

Marit Kleven and Trygve Rinde in front of an early model of the Marine Donut. Photo: Ragnhild Johansen / Varden.

Kleven becomes enthusiastic when discussing the industrial area of Grenland.

There is so much to be proud of in our region! It's incredibly cool that there are companies willing to invest and build the world's largest floating "plastic donut" here in Bamble. The beauty is that the breadth of expertise available here can contribute to their success.

Kleven has no doubt that the specialized expertise in the area can also contribute to Norway's major focus on aquaculture. Over the course of 30 years, the Norwegian aquaculture industry has increased its production of salmon and trout from around one hundred thousand tons to 1.3 million tons today. It is a declared political goal that aquaculture production should increase to five million tons in 2050, but only if it can be done sustainably. The floating closed aquaculture facility that Marine Donut represents is part of the solution. In such a facility, one can secure against fish escape, sea lice, and collect waste more efficiently than with today's traditional cages.

"The ability to calculate and control the conditions for the salmon swimming inside the donut also ensures that the salmon are well taken care of. Process industrial expertise and animal welfare should therefore be closely linked because we would prefer to know that the fish we eat for dinner have had a good life. It's exciting that simulations we do at Ranold can contribute to happy salmon! That makes me proud," concludes Kleven.

The incline test was conducted for half-raised position and for maintenance position (empty) by adding water in ballast zone 1 and measuring tilt in this direction. This volume corresponds to 53.4 m3, or for the typical seawater density (1025 kg/m3) about 54.7 tons:

In the half-raised (partial load) position, Bluegreen personnel could confirm that Marine Donut lay stable with tilting along the X-axis (no "rolling"). This proves that there is a good correlation between calculation and physical measurement.

The incline test in the maintenance position (empty) did not show enough deviation to measure differences in distance from bollards to the water surface before and after ballasting. The inclinometer from ABB indicates tilt measurements that vary within the uncertainty. The conclusion here, too, is that there is a correlation between calculation and physical measurement with a negligible tilt angle.