The construction of NOAH's new facility for dewatering inorganic hazardous waste is progressing as planned. Bluegreen provides prefabrication and installation.

It is the Swedish company Granitor that won the contract for the construction of the facility, and they engaged Bluegreen as a subcontractor with responsibility for non-metallic piping. Ida Nilsen is the foreman for Bluegreen on the project.

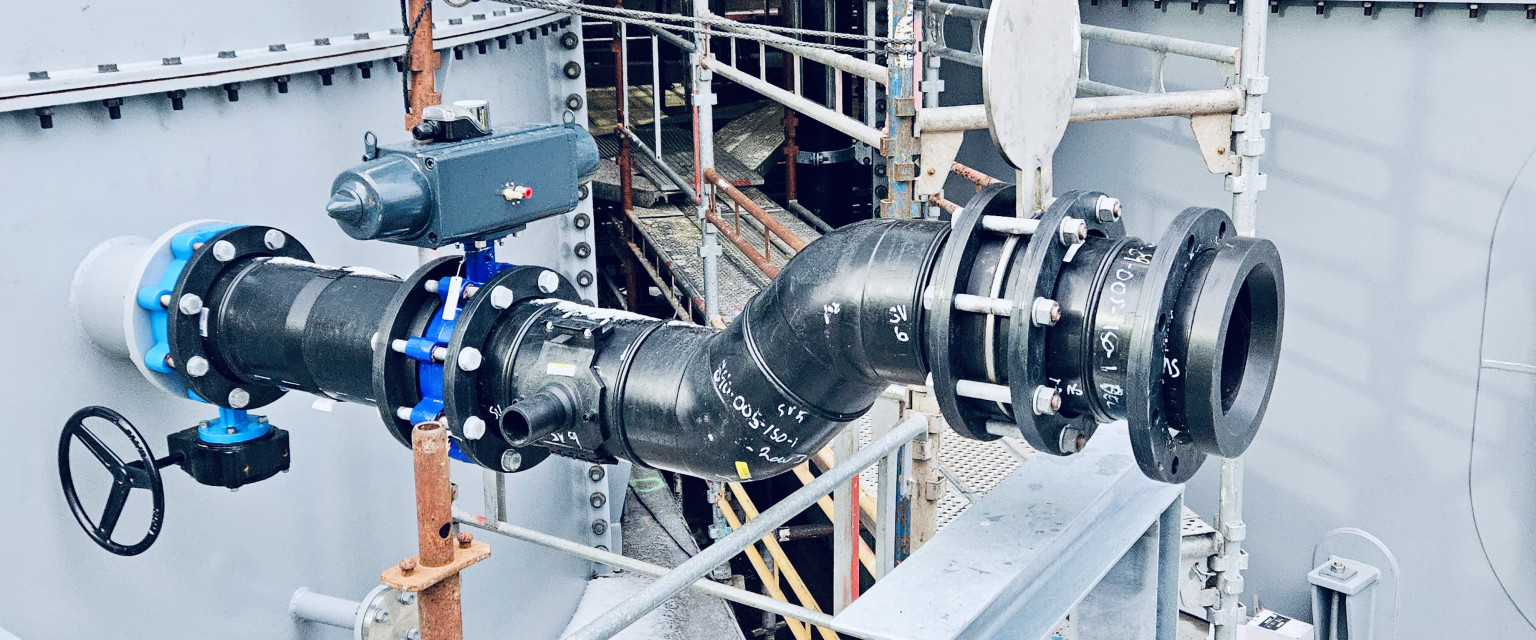

"We work on both the prefabrication of pipe components such as coils and bends, as well as the installation and assembly of these on Langøya," explains Nilsen.

Read more: New technology increases capacity

Our delivery started in August and is planned to be completed in February. Around ten people from Bluegreen are involved in the project.

"We have a team of six handling installation and assembly on Langøya, while 4-5 individuals work on prefabrication in our workshop.

Nilsen praises the collaboration with Granitor.

"Granitor is very organized and easy to work with. They have full control of all drawings and documentation, and they have a constructive and good dialogue. When unforeseen things happen, as they always do in such a large project, it never becomes a problem. They have the attitude: 'we'll solve this.'"

Since Granitor is experts in steel and has less experience with thermoplastics, we find that they have high trust in our expertise.

"They always listen to us and trust our suggestions," says Ida.

Read more: From apprentice to foreman in 2 years

Nearly 3 km of PE pipes have been ordered for the project! They come from the Austrian company Agru and are delivered via GPA as their Norwegian distributor.

"In this project, there were strict requirements for documentation. Granitor has promised full traceability of all parts and all welds. That is one of the reasons why Agru was chosen as the plastic supplier. Their products have very high quality, and all documentation is in perfect order," says Nilsen.

Our own welding work is documented in welding logs, where we note down pressure, temperature, and dimension, among other details.