The plastic workshop is in many ways the hub of Bluegreen's operations. Parts are prefabricated there for our own projects, such as Marine Donut and Granitor/NOAH, and we create customized products for a variety of customers.

The workshop department is led by Kristoffer Rønning. He oversees a team of 12 people, including a couple of apprentices and a technical draftsman/designer. Most of them work inside the workshop, but he also supervises a few resources working outdoors, such as welding pipes in trenches.

– The turnover in the workshop has steadily grown since we started, and once again, we're reaching an "all-time high," says Rønning.

The projects are divided approximately 50/50 between internal and external endeavors.

– We've worked on about 150 projects in 2023, ranging from small to large, says Rønning. – In addition to that, there are internal deliveries, where Marine Donut naturally constitutes a significant portion. There was a need for a lot of prefabrication and special parts. This fall, we had a team working on the Granitor project, where we created prefabricated pipe parts and coils.

Read more: Construction of the special waste facility is proceeding according to plan

Regardless of whether the delivery is external or internal, one thing is common to all workshop projects: they require customization.

– We rarely produce something identical; everything is mostly customized, says Rønning. – Whether it's a part or a finished product, such as HDPE manholes, we can create almost anything!

Read more: Tailor made solutions

– We work either based on customer drawings, or we contribute to product design and technical drawing, from idea to the finished product.

On the list of assignments the workshop has completed in the past year are items such as filters, wells, pipe components, buoyancy elements, and tanks.

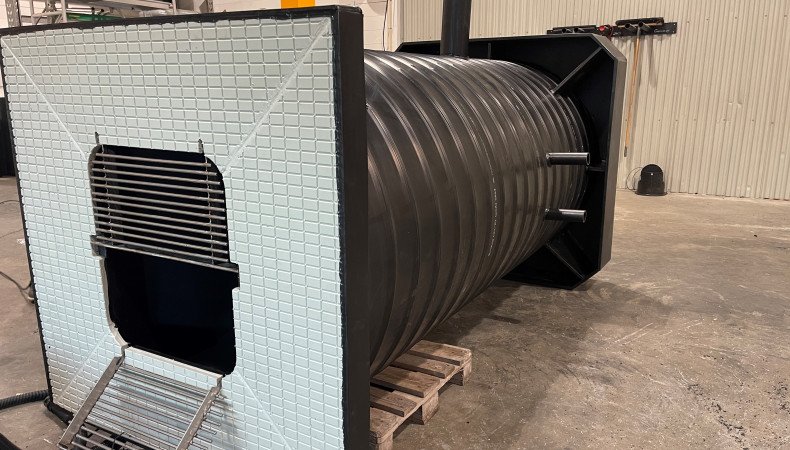

Buried tank for chemical spills. The tank is equipped with a safety barrier in case of a potential leak.

Customer: BKS Industries

Pumping station for Porsgrunn Municipality with Ø1600 mm.

Customer: Sulzer

376 meters of perforated ventilation ducts for four new wellboats.

Customer: Aas Mek - Vestnes

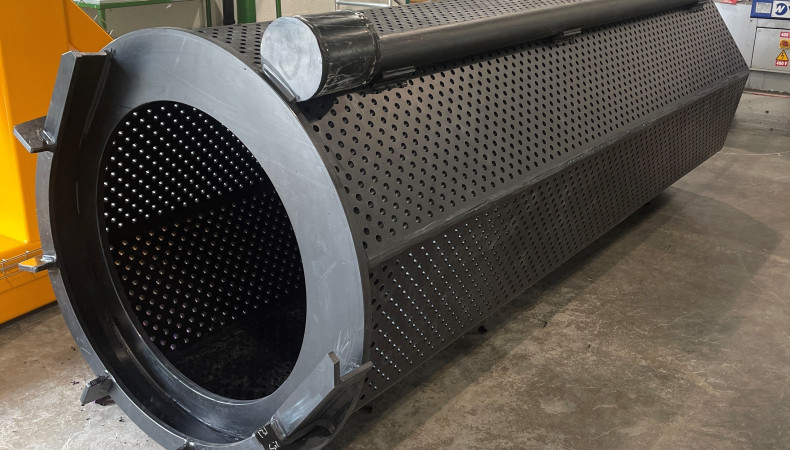

Intake strainer for the sea pipeline in the carbon capture/CCS project Langskip.

Customer: Aker Solutions