Bluegreen is part of an exciting carbon capture project in Grenland called Grenland Industrial Carbon Capture and Storage (GICCS). The project involves 15 partners within industry, technology, and research and aims to reduce more than one million tons of CO2 emissions in the area.

GICCS, led by Powered by Telemark, seeks to find solutions to further reduce CO2 emissions in addition to the ongoing projects in Grenland, which include a CCS project at Heidelberg Materials in Brevik and Yara's plans for CO2 reduction through electrification and green ammonia production.

Magnar Bakke, project manager for GICCS, states: "We have found that it is possible to capture, separate, and store an additional 1.2 million tons of CO2 from process industry companies in Grenland."

Four major industrial companies, including INEOS O&P and INEOS Inovyn at Rafnes, Eramet at Herøya, and Heidelberg Materials in Brevik, are involved in the project along with SINTEF, the University of South-Eastern Norway (USN), and several supplier companies, including Bluegreen. The project has explored possibilities for shared solutions to capture CO2 emissions from these industrial companies.

Read more: Sea pipelines for carbon capture facility

Funded by Gassnova through the Climit program and the companies themselves, the project has identified high costs as one of the major challenges for broader implementation of CO2 capture (CC) from land-based industries.

GICCS has proposed a concept where separate absorbers are installed at each factory location, while a common desorber column (stripper) is placed at a central location, preferably where surplus heat is available. In Grenland, Herøya Industrial Park is considered the ideal location for this purpose.

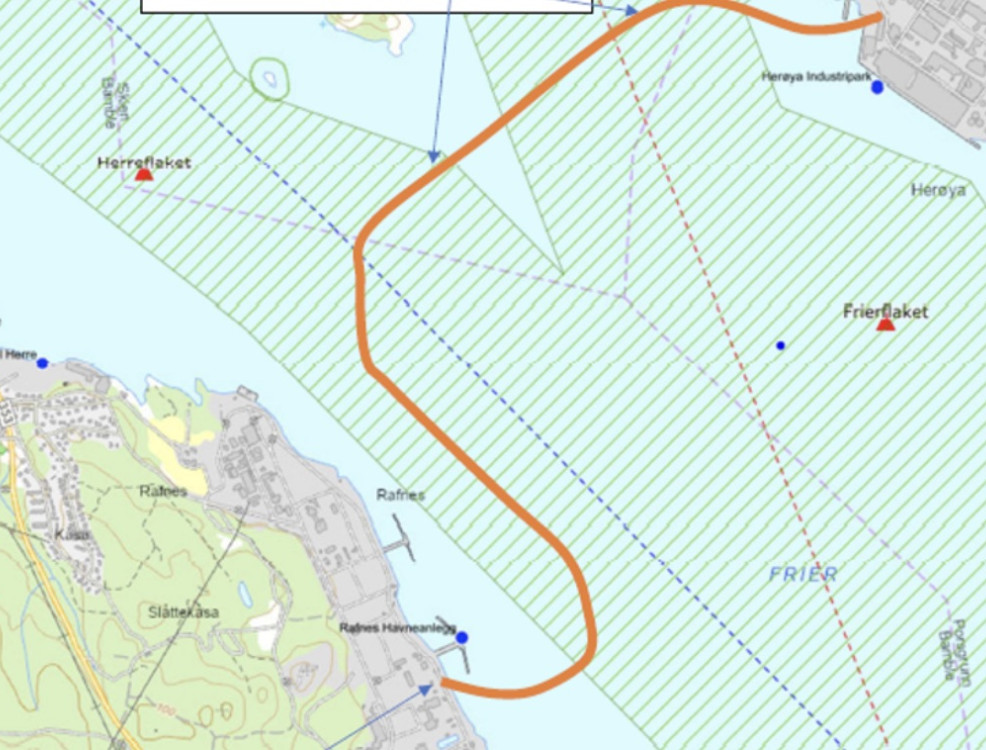

To transport the CO2-rich amine between the absorbers and the desorber, pipelines under Frierfjorden are required. Bluegreen, together with Pipelife and SINTEF, has looked at proposed solutions for these pipelines.

"There is limited data on the use of HDPE pipelines for the transport of amines, so further research is needed," says Elg Ragnar Thunes, partner at Bluegreen and one of the contributors to this project.

"But preliminary experiments suggest that it will work fine at temperatures of 40 degrees Celsius. PE pipes are a cost-effective material with high strength and resistance to corrosion, and they can be recycled after use.

The project has proposed this route for the two approximately 3 km long pipelines between INEOS Rafnes on the west side of Frierfjorden and Herøya Industrial Park on the east side.

The GICCS project has shown that shared solutions are possible and has encouraged companies to consider investing in CO2 capture facilities. Increasing environmental requirements and rising CO2 taxes will likely increase the need for CO2 capture and make it more attractive for the industry to invest in such facilities in the future.

"The goal of GICCS was to see opportunities to develop shared solutions for CO2 capture from industry. Now, the companies have an overview and the challenges on the table," concludes Bakke.